- Home

- Capsule Counting Fil…

Capsule Counting Filling Packaging Line

What’s the functions of capsule Counting Filling Packaging Line?

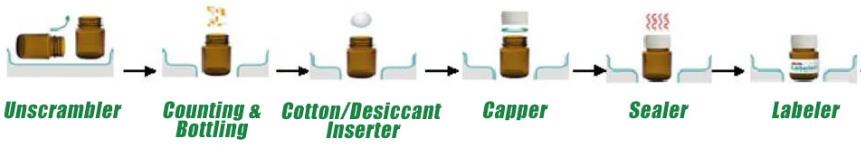

A capsule counting filling packaging line is a comprehensive system designed for the efficient counting, filling, and packaging of capsules or tablets or softgel. It typically consists of several interconnected machines working together to automate the entire process. The main functions of a capsule counting filling packaging line include:

Capsule Counting: The line includes a high-speed capsule counting machine that accurately counts the desired number of capsules or tablets. This ensures precise dosage and eliminates the need for manual counting.

Filling: Once the capsules are counted, the line has a filling mechanism that automatically fills the counted capsules into individual containers, such as bottles, blister packs, or pouches. The filling process ensures consistent and uniform distribution of capsules.

Packaging: After filling, the line incorporates a packaging machine that securely seals the containers, ensuring product safety, integrity, and protection from external factors such as moisture or tampering. Different packaging formats, such as bottles with caps, blister packs, or pouches, can be accommodated depending on the specific configuration of the line.

Labeling: Some capsule counting filling packaging lines integrate labeling machines to apply product labels, including important information like dosage instructions, ingredient lists, and batch numbers. This ensures proper identification and compliance with regulatory requirements.

Inspection and Quality Control: The line may include inspection systems, such as vision systems or metal detectors, to detect any defects, contaminants, or inconsistencies in the capsules or packaging. This helps maintain product quality and ensures adherence to safety standards.

Overall, a capsule counting filling packaging line offers a comprehensive solution for efficiently processing and packaging capsules or tablets, reducing manual labor, improving accuracy, and maintaining product integrity throughout the production process.

What affect the speed of capsule counting filling packaging line?

Several factors can affect the speed of a capsule counting filling packaging line. Here are some key factors:

Machine Capacity: The counting capacity and design of the machines within the line, including the capsule counting machine, filling machine, and packaging machine, play a significant role in determining the overall speed. Higher-capacity machines can handle larger volumes of capsules, resulting in faster processing rates.

Capsule Characteristics: The size, shape, and characteristics of the capsules or tablets or softgel being processed can impact the speed of the line. Some capsules may require special handling or have properties that affect their flow or filling accuracy. Irregularly shaped or fragile capsules may require more time and precision during the counting and filling process, leading to slower speeds.

Capsule Changeovers: If the line needs to process multiple capsule sizes or variants, frequent product changeovers can prolong the overall processing time. Switching between different capsule sizes or formulations requires adjusting the machines, settings, and sometimes replacing components, which can impact production speed.

Operator Skill and Training: The proficiency and experience of the operators handling the line can influence the processing speed. Well-trained operators who understand the equipment and processes can operate the line more efficiently, maximizing its speed potential.

Line Configuration and Integration: The overall layout and configuration of the line, including the arrangement of machines, conveyors, and material flow, can impact its speed. An optimized configuration and proper integration of the machines can minimize downtime, reduce product transfer times, and improve the overall speed of the line.

Automation and Controls: The level of automation and controls present in the line can affect processing speed. Advanced automation features, such as robotic handling systems, synchronized controls, and efficient material handling mechanisms, can streamline the process and minimize cycle times, leading to faster speeds.

Maintenance and Equipment Condition: Regular maintenance and upkeep of the machines within the line are essential to ensure optimal performance and speed. Proper lubrication, calibration, and timely replacement of worn-out parts are crucial for maintaining the line’s efficiency.

By considering these factors and optimizing the relevant aspects, it is possible to enhance the speed and productivity of a capsule counting filling packaging line.