Description

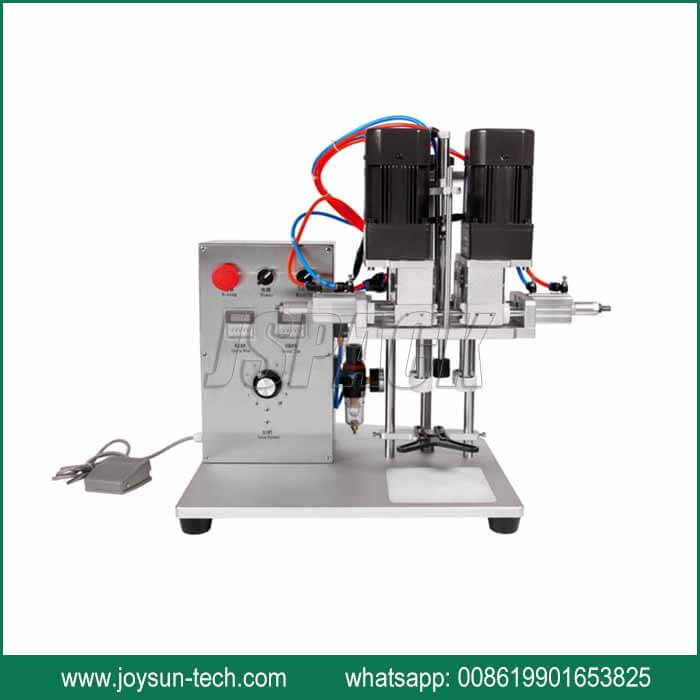

Bottle Screw Capping Machine

Description

The Bottle Screw Cap Machine is a specialized device used to apply screw caps to bottles with efficiency and accuracy. It finds applications in industries such as food and beverage, pharmaceuticals, and cosmetics. This machine automates the process of placing screw caps onto bottles, ensuring a secure and consistent closure. It works by positioning the bottle under a cap feeder, which supplies the caps to the machine’s capping head. The capping head then precisely applies the screw cap onto the bottle, exerting the required torque for a tight seal. The Bottle Screw Cap Machine is designed to handle various bottle sizes and cap types, offering production flexibility. It enhances productivity by delivering high-speed and reliable cap application, reducing manual labor and increasing throughput. This machine provides an efficient and streamlined solution for industries that require consistent and efficient screw cap sealing of their products.

Parameter

| Capacity | 30-120 BPM |

| Applicable cap size | φ30-φ80mm (customization is available) |

| Applicable bottle diameter | φ30-φ120mm |

| Applicable bottle height | 50- 200mm |

| Power supply | 1P 220V 50/60HZ |

| Power | 1.3KW |

| Air pressure | 0.4-0.6MPA |

| Air consumption | 0.5m3/M |

| Weight | 550kg |

| Dimensions | 2100x850x1600mm |

Characteristics

The Bottle Screw Cap Machine offers versatile cap compatibility, efficient cap feeding, precise cap application, adjustable torque control, high-speed operation, easy bottle integration, user-friendly interface, durable construction, safety features, and easy maintenance. It is a valuable solution for reliable and high-quality screw cap sealing of bottles.