Description

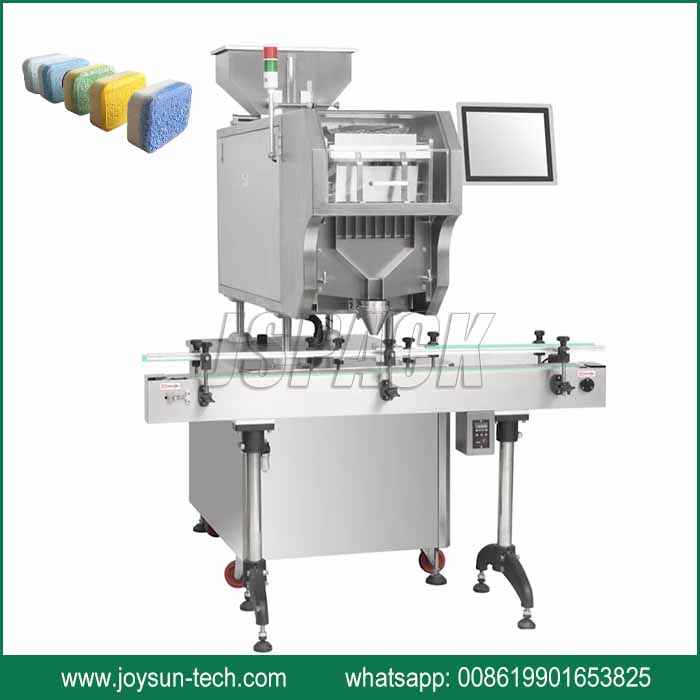

Capsule Counting Machine

The Difference Between Semi-Automatic and Automatic Capsule Counting Machine.

The main difference lies in the level of automation and the degree of human intervention required during the counting process. Here’s a breakdown of the key distinctions:

Semi-Automatic Capsule Counting Machine:

Manual Loading: In a semi-automatic capsule counting, capsules are usually loaded into the machine manually by an operator.

Manual Operation: The counting process is initiated and controlled by the operator. The machine assists in counting the capsules accurately but requires human intervention.

Lower Capacity: Semi-automatic capsule counters generally have a lower capacity, meaning they can count a smaller number of capsules per minute compared to their automatic counterparts.

Limited Automation: While the capsule counter provides some level of automation in the counting process, semi-automatic counters typically require operator involvement for various steps, such as capsule loading and releasing counted capsules.

Affordability: Semi-automatic counters are generally more affordable compared to fully automatic ones.

Automatic Capsule Counting Machine:

Automated Loading: Automatic capsule counters have an integrated loading system that automatically feeds capsules into the machine, eliminating the need for manual loading.

Fully Automated Operation: The counting process is fully automated, with minimal or no operator involvement required once the machine is set up and running.

Higher Capacity: Automatic capsule counters have a higher capacity and counting speed, allowing them to count a larger number of capsules per minute.

Advanced Features: They often include advanced features like automatic rejection of damaged capsules, dust extraction systems, and integrated sorting mechanisms.

Higher Cost: Automatic capsule counters are generally more expensive compared to semi-automatic models due to their advanced automation capabilities.

The choice between a semi-automatic and automatic capsule counter depends on factors such as production volume, desired level of automation, budget, and specific requirements of the application.

| Capacity | Max.4200 pcs/min |

| Control Method | Touch screen control |

| Hopper Capacity | 20L |

| Capsule size | thickness: 3-10mm; diameter: Ø3-24mm; length: 3-26mm |

| Bottle size | diameter: Ø30-80mm; height: 40-200mm |

| Motor Power | 110V~220V/50-60Hz /1.5kW |

| Net Weight (kg) | ~100kg |

| External Dimensions | 1600mm×1700MM×1750MM |

| Machine Material | Main parts material 304 |