Description

Desiccant Insertion Machine

What’s the function of Desiccant Insertion Machine

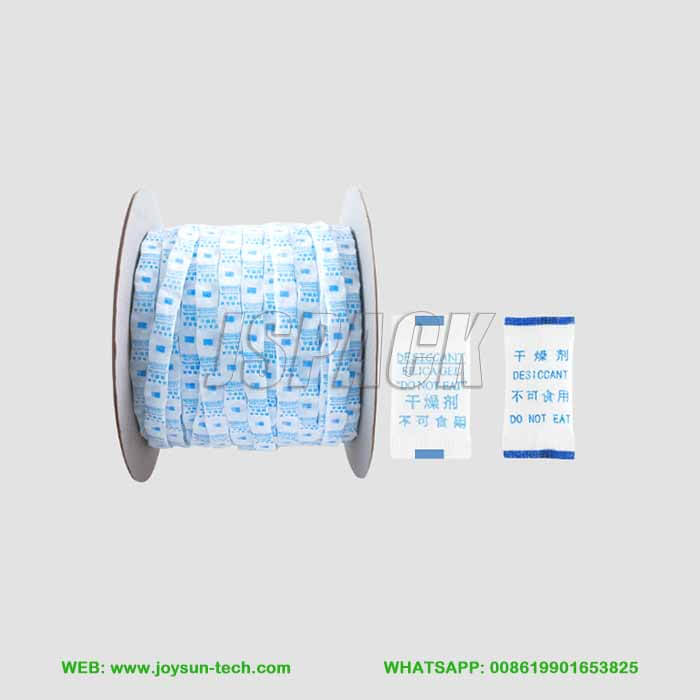

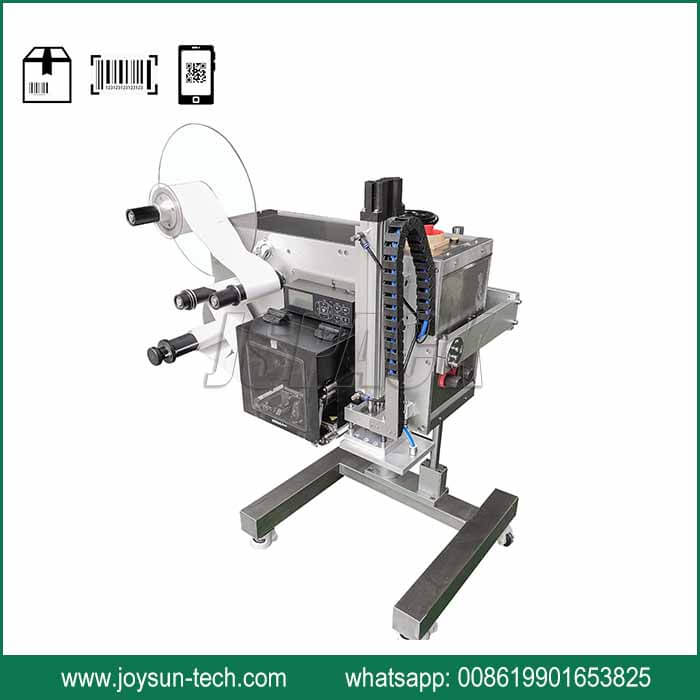

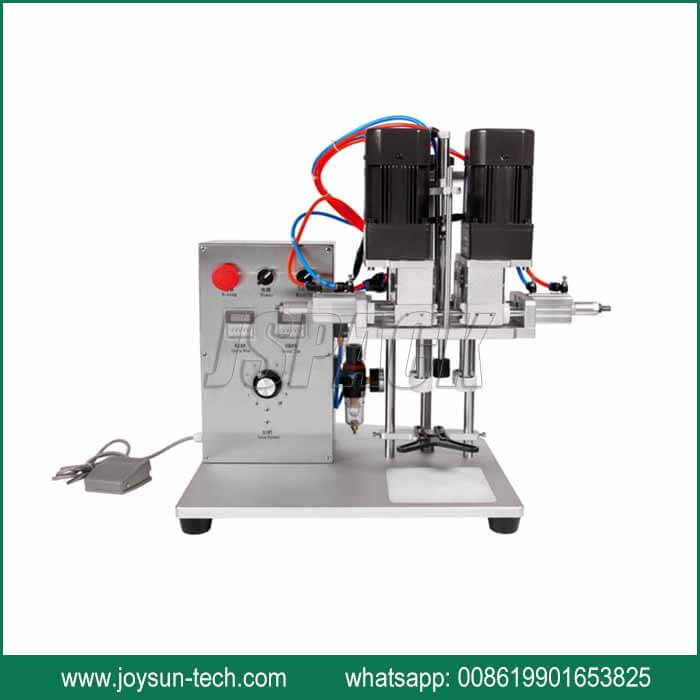

The function of a Desiccant Insertion Machine is to automate the process of inserting desiccant packets into product packaging. Desiccants are moisture-absorbing substances typically used to protect sensitive products, such as electronics, pharmaceuticals, or food, from moisture damage during storage or transportation.

The Desiccant Insertion Machine is designed to handle desiccant packets of various sizes and shapes. It automates the placement of desiccant packets into product packaging, ensuring accuracy and consistency. The machine typically incorporates a hopper or feeder system to supply desiccant packets, which are then precisely inserted into the designated area within the product packaging, such as a bottle, pouch, or box.

By automating the desiccant insertion process, this machine offers several advantages. It significantly improves efficiency by reducing manual labor and increasing production speed. It ensures the proper placement of desiccants, minimizing the risk of errors or inconsistencies that can occur with manual insertion. The machine also enhances product quality by maintaining the integrity of sensitive products and extending their shelf life by protecting them from moisture.

Parameter

| Model | JSDI-200 |

| Capacity | 40~70BPM |

| Applicable bottle size | Ø30-70mm |

| Applicable desiccant size | 10-30mm(W)20-50mm(L) |

| Dimensions | 1400x500x1550mm |

| Weight | 190Kg |

| Power | 350W |

| Power supply | 1P 220V/50~60Hz |

What’s Advantages of Desiccant Insertion Machine

The Desiccant Insertion Machine automates the process of placing desiccant packets into product packaging. Its advantages include increased efficiency, consistent placement, versatility, enhanced product protection, cost savings, streamlined operations, quality assurance, and scalability. Overall, it optimizes the desiccant insertion process, ensuring efficient and precise packaging while safeguarding products from moisture damage.