Description

High Speed Pill Counting Machine

In a high-speed pill counting machine, several important factors play a significant role in ensuring its effective operation and performance. Here are some key considerations:

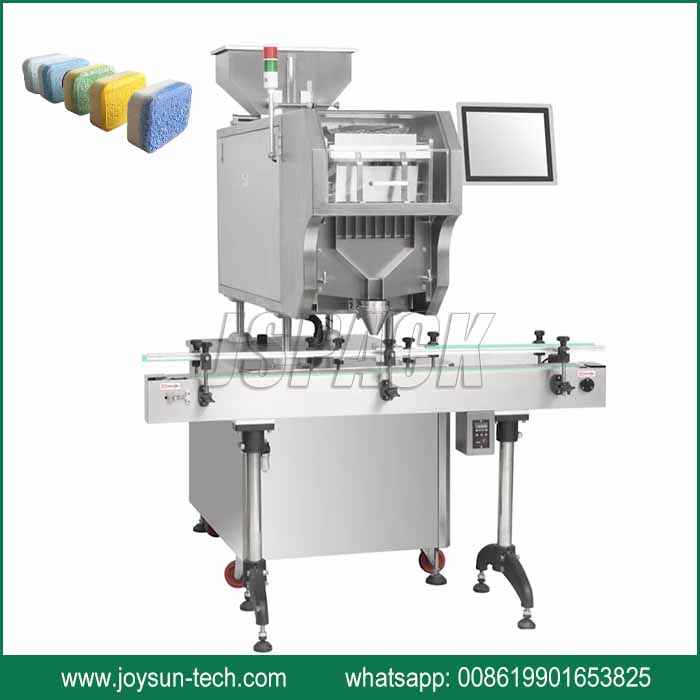

Counting Accuracy: The primary objective of a ultra-high speed pill counting machine is to achieve precise counting results. Ensuring high accuracy is crucial to avoid errors in medication dosage or product quality. Advanced counting technologies, such as dual-channel counting with photoelectric sensors, can enhance accuracy.

Counting Speed: high speed pill counting machines are designed to handle large volumes of pills efficiently. The speed of the machine is a critical factor to improve productivity and meet high production demands. Faster counting speed can significantly increase output and efficiency.

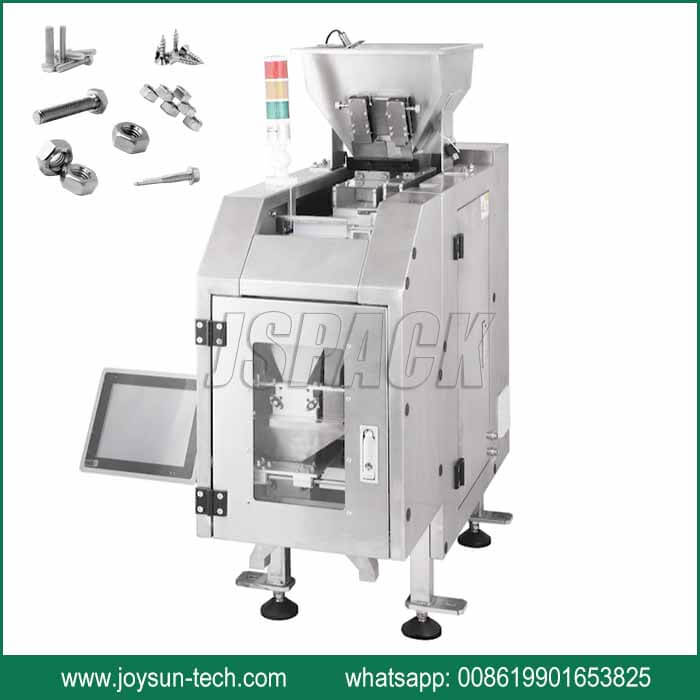

Compatibility with Pill Types: Pill properties, such as size, shape, and material, can vary significantly. An important consideration for an ultra-high pill counting machine is its ability to handle a wide range of pill types, accommodating different sizes and shapes to ensure versatility and adaptability.

Sorting and Rejecting Capabilities: Machine malfunctions or defective pills occasionally occur. An effective high speed pill counting machine includes sorting and rejecting mechanisms to identify and separate substandard or damaged pills from the counted batch. This feature helps maintain product quality and accuracy.

Ease of Use and Maintenance: Complex machinery like ultra-high pill counting machines should be user-friendly in terms of operation and maintenance. Intuitive controls, clear instructions, and easy access to cleaning and maintenance tasks enhance productivity and reduce downtime.

Integration with Packaging Systems: Often, pill counting machines are integrated with downstream packaging systems. Seamless integration, through compatibility with conveyors or robotic interfaces, can improve the overall efficiency of pharmaceutical production lines.

Validation and Compliance: In the pharmaceutical industry, compliance with regulatory standards and validation requirements is crucial. Ultra-high pill counting machines should adhere to applicable regulations, such as Good Manufacturing Practices (GMP), and facilitate documentation and validation processes as needed.

Data Management and Connectivity: The ability to store counting data, generate reports, and interface with other systems for data sharing or analysis can enhance process control and facilitate quality assurance measures.

Considering these important factors enables the selection and implementation of a reliable and high-performing ultra-high pill counting machine in pharmaceutical manufacturing or packaging environments.

| Speed | 25 – 80 bottles/min |

| Control Method | Touch screen control |

| Hopper Capacity | 20L |

| Motor Power | 110V~220V/50-60Hz /1.5kW |

| Net Weight (kg) | ~550kg |

| External Dimensions | 1800mm×1600MM×1650MM |

| Machine Material | Main parts material 304 |